Embracing Cutting-Edge 3D Printing in Customized Home Fabrication

In the fast-changing world of home improvement, innovative manufacturing techniques are steadily reshaping how custom parts and decorative elements are produced. One impressive breakthrough comes from the realm of 3D printing, where researchers have recently demonstrated a fresh method using a water-soluble, salt-like granular polyacrylamide to create sacrificial molds. Although this might sound more at home in a high-tech laboratory than on the home improvement workbench, the underlying ideas offer notable promise for home remodelers and creative DIY enthusiasts alike.

This opinion editorial takes a closer look at this emerging technology, breaks down the tricky parts of the process, and explores how home professionals can potentially harness these advances for everything from custom fixtures to innovative design solutions. Let’s dive in and get into the little details behind this exciting development.

Revolutionizing Materials with Salt-Like Granular Polyacrylamide

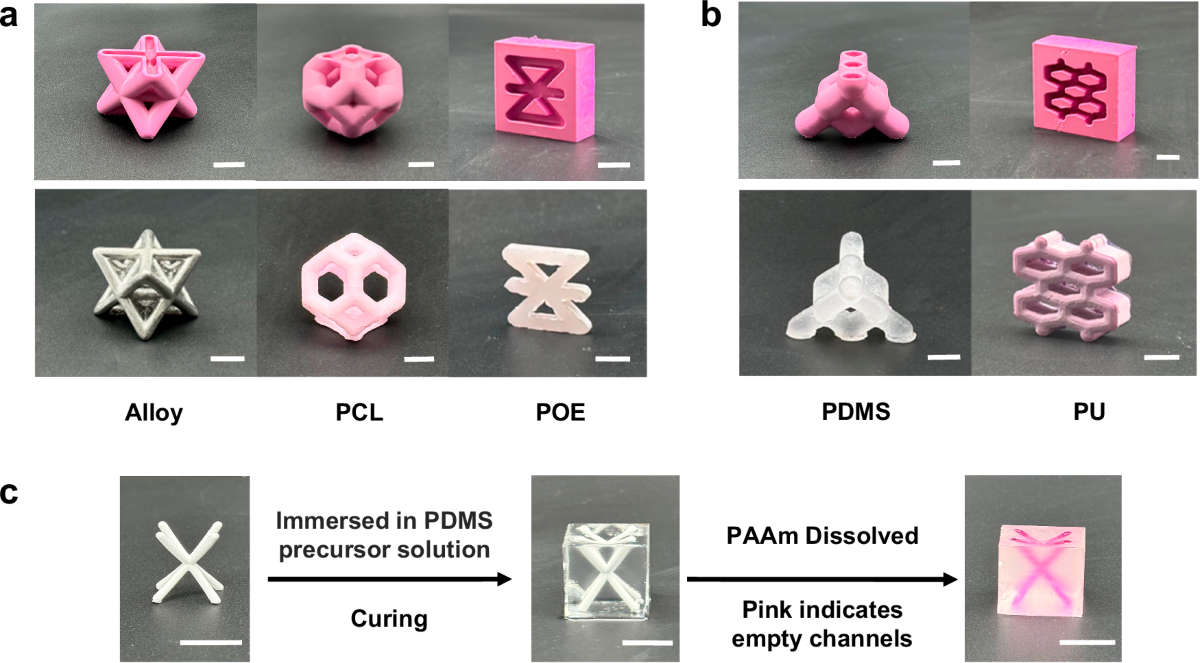

The core of this innovation lies in utilizing a unique form of polyacrylamide. Unlike traditional 3D printing materials that demand photoactive resins or require extensive post-processing, this new technique leverages a water-soluble granular structure. When 3D printed via digital light processing (DLP), this specially formulated polyacrylamide molds act like salt. They can be rapidly dissolved in neutral water at room temperature, leaving behind precisely formed replicas of sophisticated designs.

For homeowners and DIY hobbyists, there may be potential benefits. The ability to cast a range of materials—from low-melting alloys to silicone rubber—could revolutionize how custom home accents, repair components, or intricate fixtures are fabricated. Imagine being able to produce exactly shaped cast parts for a custom door handle or decorative molding directly from a durable sacrificial mold that easily washes away, leaving only your finished product.

Introducing the Innovation: What Is Granular Polyacrylamide?

At its heart, granular polyacrylamide is created through a process known as polymerization-induced phase separation (PIPS). In this process, acrylamide (a common hydrophilic monomer) is mixed in a DMF (N,N-dimethylformamide) and water solvent. Under the influence of light from a DLP printer, the solution undergoes rapid gelation, causing the polyacrylamide chains to self-assemble into a collection of microscopic granules. These granules fuse together to form an intricate mold that is stable during casting yet dissolves quickly in water.

This particular approach sidesteps some of the confusing bits and tangled issues usually associated with conventional crosslinked polymer networks. Instead of using chemical crosslinkers that often lead to nerve-racking post-processing steps or high-temperature curing, the process here relies on a smart control over phase separation and molecular weight. The result? A versatile, water-soluble mold that offers both high precision in shape and ease of removal.

A Closer Look at the Technology

While the scientific details might seem intimidating at first, a breakdown of the process reveals several key components that are valuable to both manufacturers and home improvement enthusiasts seeking to explore new production methods.

Step-by-Step Process Overview

Here’s a simplified overview of how this method works:

- Resin Preparation: The process begins with a carefully formulated liquid resin where acrylamide is mixed with the appropriate amounts of DMF and water. Tiny improvements like the use of a chain transfer agent help control molecular weight, which in turn affects the mold’s dissolution speed.

- DLP 3D Printing: Using a digital light processing printer, the resin is exposed to specific wavelengths of light, triggering rapid polymerization. This step forms layer-upon-layer of the granular mold structure.

- Phase Separation and Gel Formation: Thanks to the polymerization-induced phase separation, the acrylamide molecules spontaneously group into granules, creating an interconnected, porous matrix.

- Dissolution: Once the secondary material (for casting) is introduced, the sacrificial mold is simply washed away using water at room temperature, thanks to its salt-like dissolution properties.

This approach reduces the need for high temperatures and aggressive chemicals, making it especially attractive for creating parts that need to maintain precise dimensions or that may be sensitive to harsh conditions.

Optimizing the Process: Fine-Tuning Molecule Sizes and Phase Separation

It turns out that the level of phase separation plays a critical role in how fast the mold dissolves when exposed to water. By controlling the solvent blend and the polymer chain length, printers can adjust the porous microstructure of the mold. A higher DMF ratio leads to larger pore sizes in the cured polyacrylamide, which translates to faster dissolution times—an essential feature when aiming for efficient production.

In laboratory comparisons, a sample with a high DMF content dissolved up to seven times faster than one with a denser structure. This kind of speed and predictability in mold removal is crucial in any indirect printing process and could potentially cut production cycles for custom home fabrication projects.

Innovative Processes and Overcoming Tricky Parts

Even in advanced home improvement techniques, there are always tricky parts and tangled issues to manage. The new process of using granular polyacrylamide is no exception, although many of the hurdles have been overcome with ingenious adjustments.

Managing Your Way Through Polymerization-Induced Phase Separation

One of the initial challenges was ensuring that the polymerization-induced phase separation created a consistent and homogeneous granular structure, free of large, problematic clumps. Traditional polymer networks usually need additional chemical crosslinkers—often leading to confusing bits in processing—but the novel approach eliminates this need.

By carefully calibrating the ratio of DMF in the mixed solvent, researchers found that the mold could be made to have optimal pore sizes without resorting to harsh conditions. Here’s a quick comparison table illustrating the effect of DMF content on the final product:

| DMF Ratio | Transparency (% Transmittance) | Phase Separation Effect |

|---|---|---|

| 0% | 93.0% | Minimal phase separation |

| 100% | 7.1% | Significant granular formation and faster dissolution |

By steering through these fine shades of difference, the process taps into a sweet spot where precision is maintained and production speed is optimized, all while keeping the process cost-effective—a key benefit for potential home manufacturing applications.

Leveling and Resin Wetting: Solving the Surface Dilemma

Another challenge tackled was the leveling and wetting of the liquid resin on the surface of the previously cured layer. After each exposure in the DLP printer, the next layer of resin must spread uniformly—a process that can often be a bit nerve-racking. Here, the researchers discovered that oxygen inhibition played a surprisingly helpful role.

Typically, oxygen from the air interferes with polymerization by creating an uncured layer on top of the resin. Instead of treating this fact as a tricky problem, the team used it to enhance resin flowability. This inhibition results in a transition from a solid to a liquid surface, ensuring the resin spreads effortlessly. This means that leveling can occur more rapidly, paving the way for a printing speed of 375 mm/h without any need for blade-assisted leveling.

This breakthrough in managing the surface wetting is particularly inspiring for those who deal with intricate mold setups when repairing customized fixtures or even when creating bespoke decorative elements for homes. It shows how a small twist—a full understanding and exploitation of a well-known phenomenon—can lead to super important improvements in overall efficiency.

Rapid Production Meets Home Project Demands

Speed is an essential factor in today’s home improvement projects. When you’re awaiting custom parts for a renovation or need a tailor-made fixture set up quickly, slow production schedules can become a significant bottleneck. The new sacrificial mold technology offers an impressive printing speed and rapid mold dissolution, which might eventually translate into faster turnaround times for custom fabrications in the home environment.

Speeding Up the Process: Detailed Insights

Thanks to the low viscosity of the AAm50-DMF100 resin (around 15 cP), spreading and wetting are achieved effectively, meaning that freshly printed layers reliably adhere and level out. With a top-down DLP approach, the team was able to achieve a printing speed that far surpasses many traditional manufacturing methods:

- Printing speed: 375 mm/h, a notable figure that points to the potential for mass customization.

- Rapid dissolution: The sacrificial mold can dissolve in neutral water at room temperature in as little as 12–23 minutes, depending on the precise formulation.

For home projects, this essentially means that even multi-step fabrication—where custom parts are cast and then the mold is removed—can be completed in significantly shorter periods compared to existing processes. Home remodelers and service professionals might see this technology paving the way for faster prototyping and production of replacement parts, custom fixtures, or decorative elements.

Advantages in Home Settings: More Than Just Speed

In addition to speed, there are several key advantages that this manufacturing method could offer to the home improvement community:

- Material Versatility: The sacrificial mold is not limited to a single type of casting material. Whether you’re working with low-melting alloys for decorative hardware, silicone rubber for flexible weatherproof seals, or even polyurethane for robust components, this method is versatile.

- Mild Processing Conditions: The entire process occurs under gentle conditions that avoid the use of extreme temperatures or harsh chemicals. This is not only safer for operators but also ensures that temperature-sensitive materials are not compromised during production.

- High Fidelity: With careful control over the granular structure, extremely subtle parts and fine details from the original design can be faithfully replicated, which is super important when custom-fitting parts for home installations.

Advantages for Home Remodelers and DIY Enthusiasts

While the research might have been conducted in a rigorous scientific realm, its implications are exciting for the everyday homeowner and local contractor alike. Imagine having the ability to produce one-of-a-kind casting molds directly in your workshop without needing specialized heavy machinery.

Customization in Home Projects

Customization is a growing trend in home improvement, and with every homeowner seeking personalized touches, the capacity to fabricate unique parts on demand is a game-changer. Here are some areas where this technology could have a direct impact:

- Custom Fittings: Create tailored components for cabinetry, doorways, or even plumbing fixtures that are exactly designed to your space.

- Decorative Molding and Fixtures: Fabricate intricate designs for crown moldings, baseboards, or decorative accents that require precise, high-resolution details.

- Replacement Parts: For older homes where original parts may be difficult to source, creating a replica of damaged or obsolete components becomes feasible.

Potential for On-Site Production

Another exciting prospect is the possibility of on-site production. With the improvement in DLP 3D printing technology and the ease of dissolving the sacrificial mold in water, local workshops or even advanced DIY enthusiasts could eventually produce parts on demand without outsourcing fabrication.

Consider these benefits:

- Reduced Lead Times: Instead of waiting for parts to be shipped from a distant manufacturer, projects can be completed more quickly with in-house production.

- Cost Efficiency: Lower production costs and a reduction in post-processing labor offer savings that can be passed directly to homeowners or even reinvested in further home improvements.

- Improved Fit and Finish: With the ability to fine-tune the granular polyacrylamide structure, very specific designs can be replicated with excellent fidelity.

Potential Challenges and Fine Details of the Approach

No manufacturing process is without its twists and turns, and while the use of polyacrylamide molds has many advantages, it also comes with a few challenges that need careful consideration.

Handling the Nitty-Gritty: Diffusion Issues and Material Interference

One of the subtle parts of the process involves addressing how the casting material interacts with the microscopic pores of the mold. During casting, especially when using low molecular weight precursors, there is a risk that the material might seep into the microscopically porous structure of the mold. This could affect the surface finish of the final product.

To manage this, some strategies include:

- Adjusting Viscosity: Lowering the viscosity of the cast material can help ensure that it flows rather than seeps excessively into the mold’s pores.

- Fine-Tuning Molecular Weight: Adding small amounts of chain transfer agents helps control the molecular weight of the polyacrylamide, balancing the mold’s mechanical strength with its rapid dissolution properties.

- Surface Treatment: In some cases, mild pre-coating or other surface treatments of the mold may further reduce infiltration and preserve the quality of the cast part.

These are the kind of little twists that manufacturers will need to figure out if they are to adopt this technology on a wide scale. Home remodelers moving into custom fabrication might initially face a nerve-racking learning curve, yet as the process gets refined, it promises to offer a highly flexible intermediate step in producing custom pieces.

Managing Residual Solvent and Compatibility Considerations

Another challenge rests in ensuring that no residual solvent remains in the mold after the printing and drying processes. Since the technique uses a blend of water and DMF before curing, proper drying is vital to avoid any adverse effects on the cast materials. The research suggests a careful, staged drying process that removes DMF, but this requires extra time and attention to detail.

Furthermore, while the mold is compatible with a variety of substances, it does have its limitations. For example, water-soluble materials like soft hydrogels may not be suitable for this method because the dissolution process would compromise the final structure.

It is important to acknowledge these challenges when considering the application of this technology for home improvements. The issues are not insurmountable, and with further refinement, they could very well pave the way for a more robust and user-friendly process in the future.

Environmental and Practical Considerations

Home improvement projects not only focus on aesthetics and performance but also on environmental impact and sustainability. The adoption of water-soluble, low-temperature processing techniques can offer several environmental benefits. Manufacturers and DIY enthusiasts might be particularly drawn to a process that minimizes the use of harsh chemicals and reduces energy consumption.

Sustainable Manufacturing for Home Projects

This process avoids high-temperature processing and aggressive chemicals that might be both costly and environmentally damaging. Some of the key sustainability aspects include:

- Low-Energy Requirements: Fast printing speeds and room-temperature dissolution collectively mean lower energy consumption during production.

- Reduced Chemical Waste: The improved process minimizes the need for hazardous chemicals, ensuring that residual waste is limited and easier to manage.

- Versatility of Materials: The ability to work with a range of casting materials allows DIYers to choose more environmentally friendly options for their home projects.

For homeowners and service professionals alike, incorporating sustainable practices into custom fabrication projects can be both a selling point and a responsible choice for the environment. As consumers increasingly demand green solutions, the potential for integrating these advanced techniques into everyday home improvement work is significant.

Balancing Cost and Innovation

Another practical consideration is the cost of implementation and equipment. While high-end DLP printers and custom resin formulations might seem off-putting initially, the long-term advantages include lower per-part production costs and heightened creativity in design. This opens up opportunities for small-scale production, local workshops, and even home-based fabrication units that might eventually rival factory methods in both speed and quality.

A cost-benefit analysis for local fabricators might include the following factors:

- Equipment Investment: Initial costs of high-resolution DLP printers versus potential savings from in-house production.

- Material Efficiency: The ability to recycle or safely dispose of water-soluble molds.

- User Training: Short-term nerve-racking learning curves balanced against long-term ease of use as the technology matures.

Future Applications and Trends in Home Services

Looking forward, this breakthrough in sacrificial mold fabrication could have wide-reaching implications for home services and custom remodeling work. Even if the current technology is primarily showcased in academic journals, its potential adaptations suggest a new horizon for on-demand, in-house part production.

Potential Impact on Custom Home Fabrication

Imagine a future where local workshops or even mobile fabrication units can produce custom, intricately designed components on demand. Whether it’s specialized hardware, bespoke decorative panels, or even replacement parts for older or specialty-built homes, the possibilities are vast.

Some of the exciting future directions include:

- On-Demand Production Centers: Local fabrication hubs that allow homeowners to order custom-designed parts with quick turnaround times.

- Enhanced DIY Kits: Kits that integrate DLP 3D printing devices and ready-to-use, water-soluble resin formulations for the home improvement enthusiast.

- Integration with Digital Design: The convergence of CAD design and 3D printing, allowing for real-time modifications that are immediately produced in high resolution.

- Collaborative Fabrication Networks: Local networks of professionals sharing designs and techniques, leading to a more creative and responsive home service industry.

There is also the prospect of using similar technologies to produce high-quality polymer foams. For instance, by infusing low-viscosity epoxy monomers into the granular mold and then allowing them to cure, a three-dimensional foam with an intricate pore structure can be created. Such foams might have applications in sound insulation, lightweight building materials, or even shock-absorbing panels for enhanced home security.

Adapting the Process for Everyday Use

With ongoing developments, this technology could soon be refined into a more user-friendly platform that even regular homeowners could safely operate. As the process evolves to become more streamlined, there is a possibility that a scaled-down version of the DLP printer could be marketed for home workshops, allowing individuals to experiment with custom designs at a relatively low cost.

Key trends to watch include:

- Automation: Easy-to-use interfaces that remove much of the intimidating technical setup required by industrial machines.

- Material Innovations: Continued research into alternative polymers that offer improved durability or specialized characteristics, thereby broadening the range of viable applications.

- Open-Source Designs: The emergence of online communities sharing CAD models and process tweaks, making the technology more accessible to curious DIYers.

Conclusion: A New Horizon in Home Custom Fabrication

As we take a closer look at this innovative method for 3D printing sacrificial molds with granular polyacrylamide, it becomes clear that this breakthrough is more than just a scientific achievement. It represents a significant step toward a future where home improvement projects can benefit from rapid, high-precision custom fabrication techniques.

By breaking down the tricky parts, managing the fine details, and finding a path through the challenges, this technology has the potential to revolutionize the way we approach home remodeling and custom fabrication. The process is not only faster and more versatile than traditional methods, but it also offers a more sustainable and cost-effective route to producing complex, tailor-made components.

Home remodelers, service professionals, and DIY enthusiasts alike stand to gain from these advancements. As this technology matures, we can expect to see more affordable, user-friendly iterations that could eventually allow individuals to produce custom parts directly in their own workshops. The possibilities range from replacing outdated fixtures in older homes to designing brand-new decorative elements that reflect a homeowner’s unique style.

Key factors that make this approach so appealing include:

- Reduced processing times thanks to rapid mold dissolution and high-speed DLP printing.

- The ability to work under mild conditions, preserving the integrity of temperature-sensitive materials.

- A sustainable, water-based process that minimizes the need for harsh chemicals and high energy consumption.

- The opportunity for enhanced customization, enabling the production of parts that perfectly match a home’s design requirements.

This new manufacturing method is not without its challenges—there are still some confusing bits related to material diffusion and the balance between molding strength and rapid removal. However, these issues are being actively addressed by researchers who are excited about the potential improvements and refinements in the near future.

For those working in home services, this represents a promising innovation that could eventually transform on-demand production. Whether it’s in small-scale fabrication workshops or as part of a larger manufacturing network, the technology has the potential to lower costs, reduce lead times, and open up new creative avenues for custom home projects.

By embracing innovative technologies like sacrificial mold 3D printing, home improvement professionals may soon find themselves with the tools to produce truly unique, high-quality components with ease. The integration of cutting-edge scientific advances into everyday practice is an exciting development—one that reflects the broader trend of innovation in home improvement and custom services.

In a time when personalization and efficiency are key, the ability to print intricate molds that dissolve away in water suggests a promising convergence between high-tech manufacturing and practical home remodeling. Homeowners and professionals alike are encouraged to keep an eye on these developments, as the future of custom home fabrication might very well be shaped by these incremental yet super important advancements.

In closing, the little details and subtle parts of this process—the precise control of phase separation, the finely tuned molecular weights, and the smart exploitation of oxygen inhibition—all combine to create a technique that is as versatile as it is innovative. As researchers continue to polish this method and make it more accessible, the day may not be far off when custom-fabricated home parts become a standard offering at local home improvement centers and workshops.

With its blend of speed, efficiency, and environmental friendliness, the granular polyacrylamide sacrificial mold technology could soon emerge as a key enabler for future home fabrication projects. It’s a technology that brings a fresh perspective to traditional manufacturing, and one that we believe will inspire many in the home services industry to explore new, creative avenues in design and production.

As we look toward a future where your local hardware store might offer custom-printed, ready-to-cast molds for your one-of-a-kind home projects, it is clear that the evolution of 3D printing is not just science fiction. It’s an unfolding reality that holds the potential to empower homeowners and remodelers to transform their visions into tangible, beautifully crafted realities—faster, greener, and more efficiently than ever before.

Originally Post From https://www.nature.com/articles/s41467-025-62674-1

Read more about this topic at

Water-soluble sacrificial 3D printed molds for fast …

Rapid Molding: Rapid Injection Molding – Custom Molding